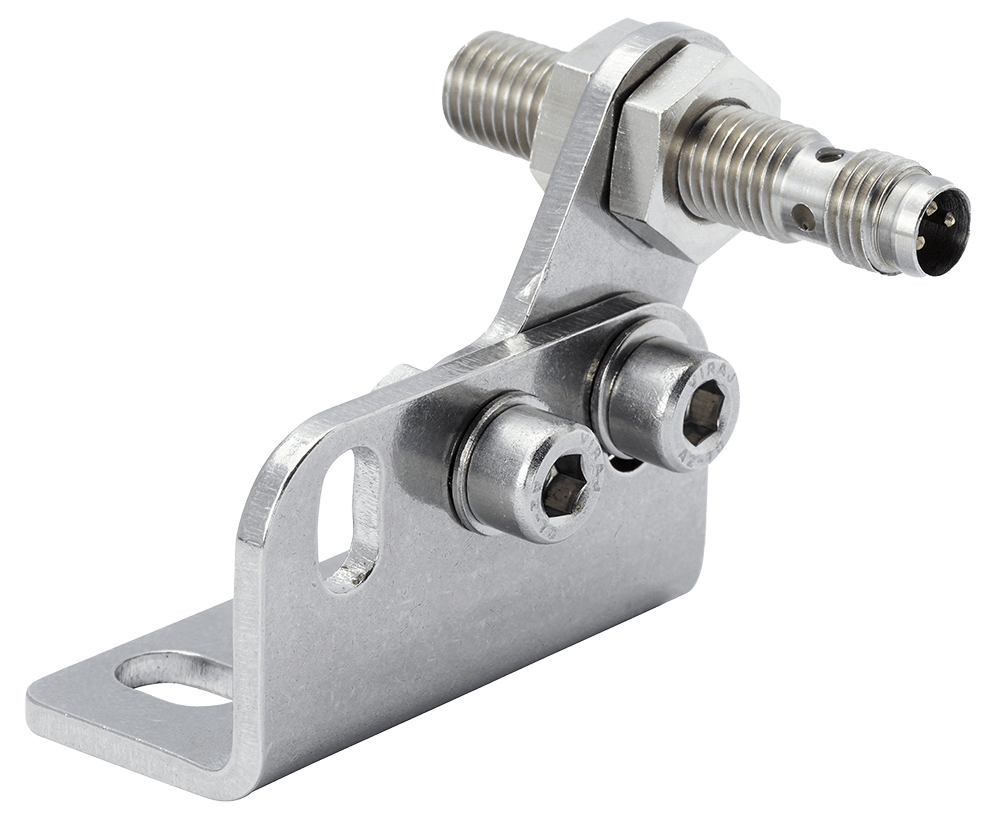

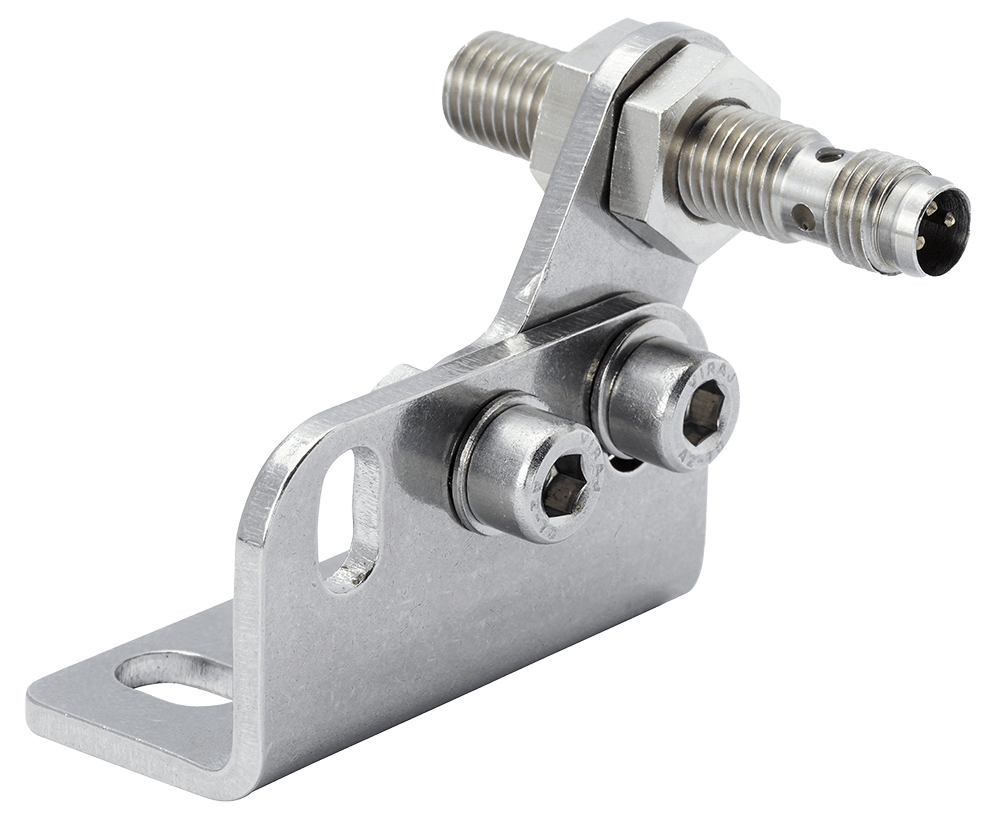

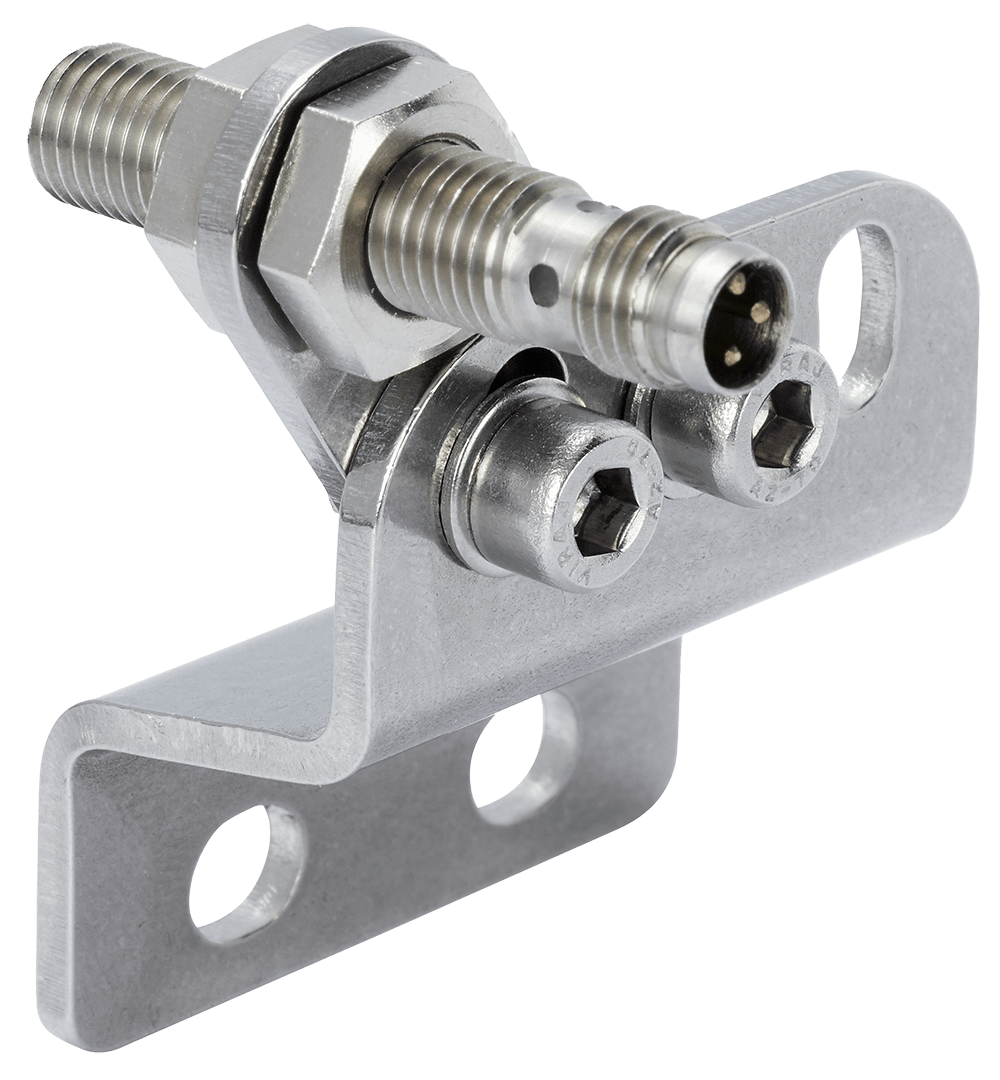

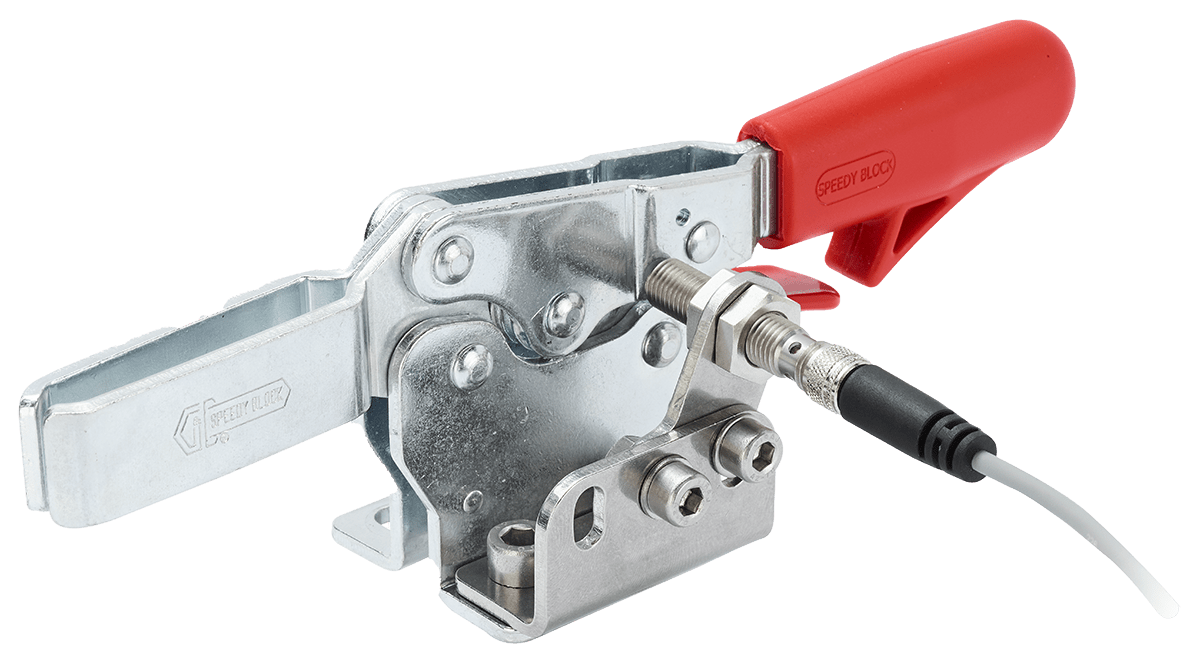

Control sensor kit

Proximity sensors remotely send a signal that the clamping tool has been closed or opened and, in case of incorrect opening caused by vibration or shock, they can trigger a lockout of the machining process, thereby promoting quality and process safety.

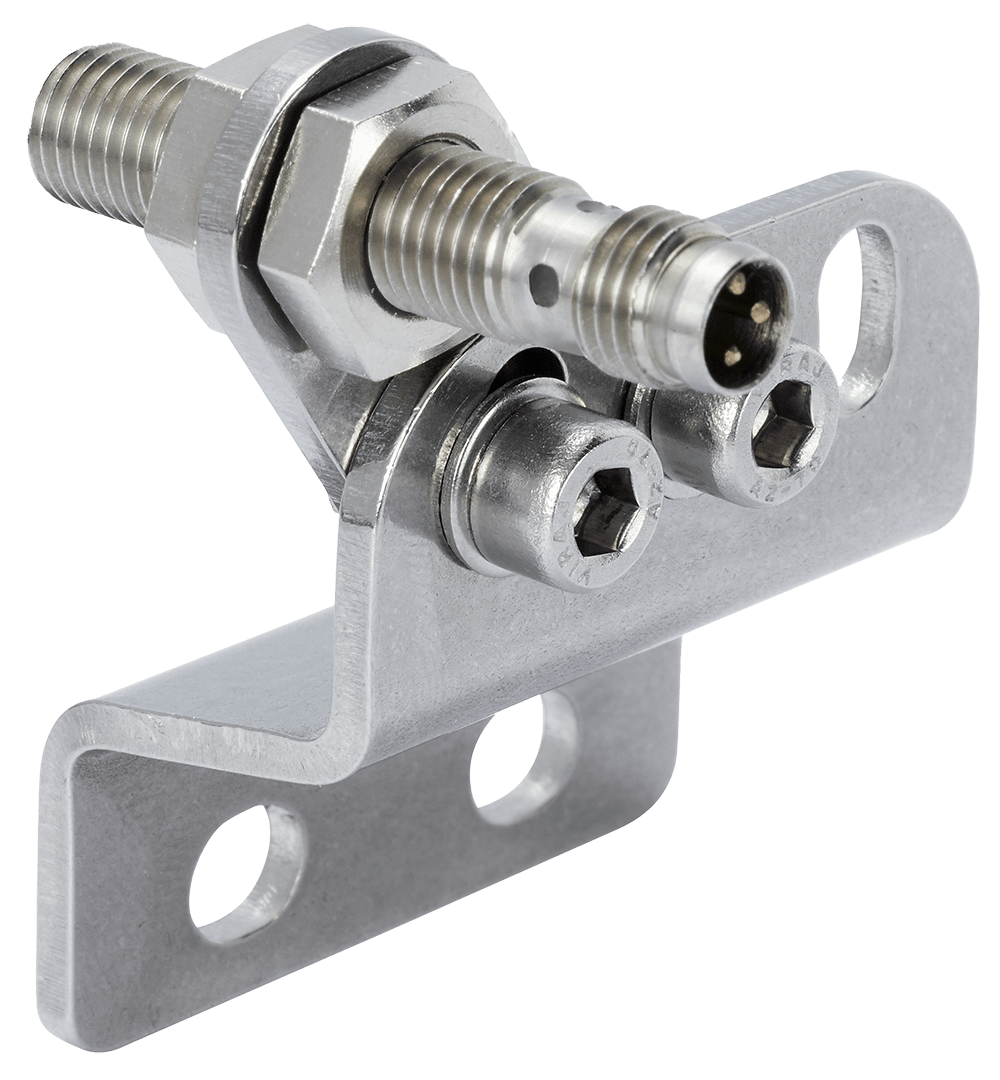

Control sensor Kit for folded base

Control sensor Kit for straight base

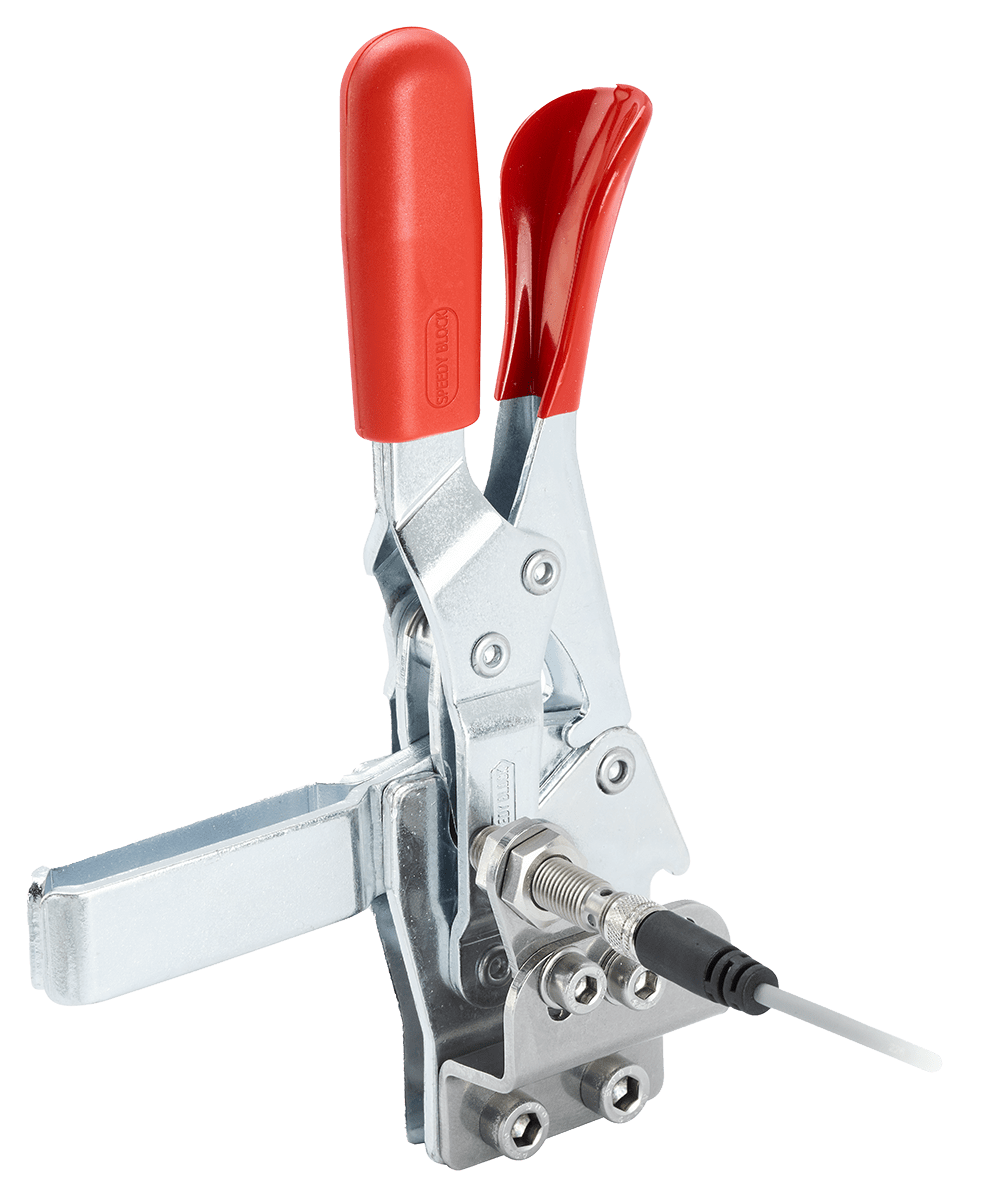

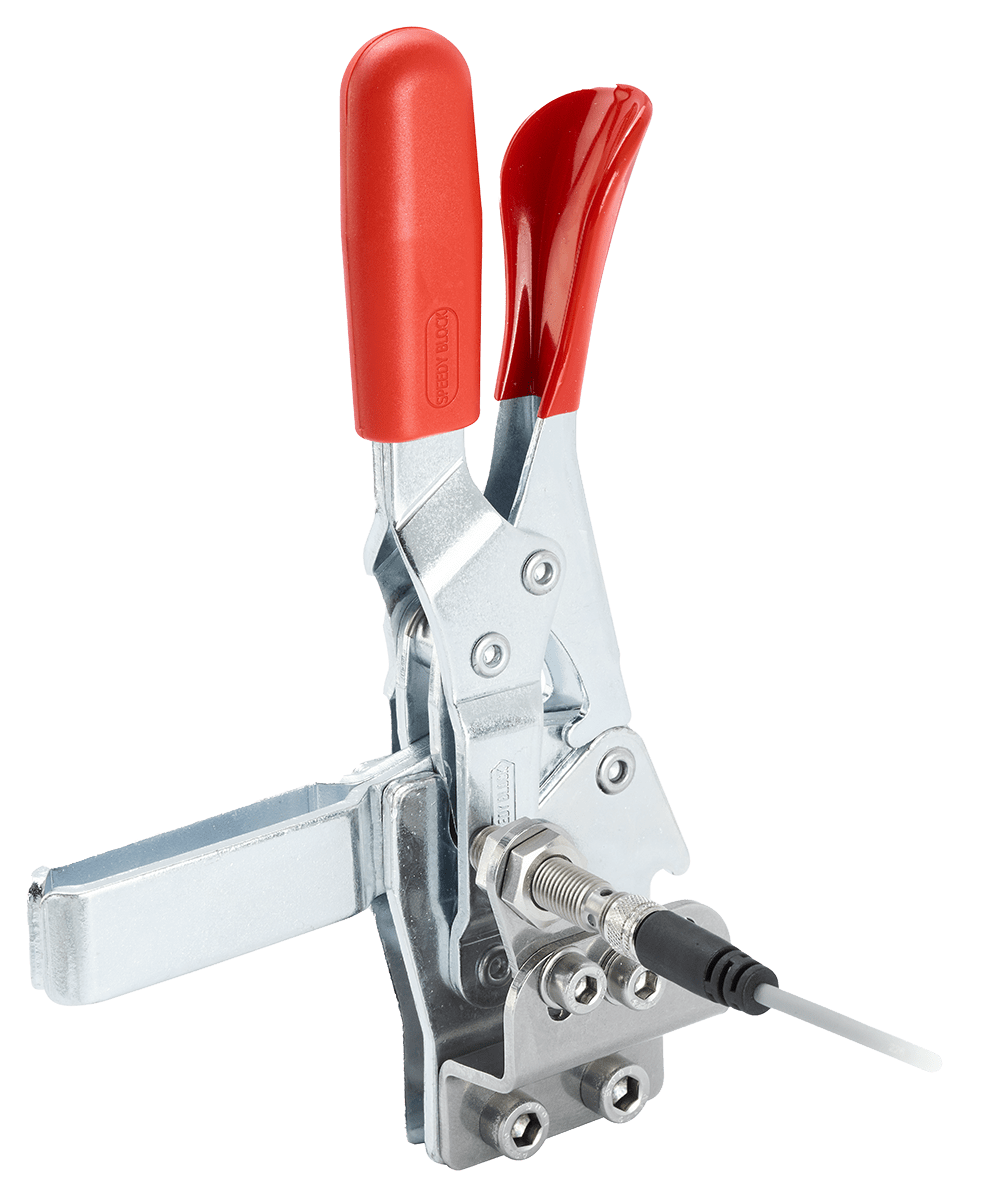

Application example on vertical series

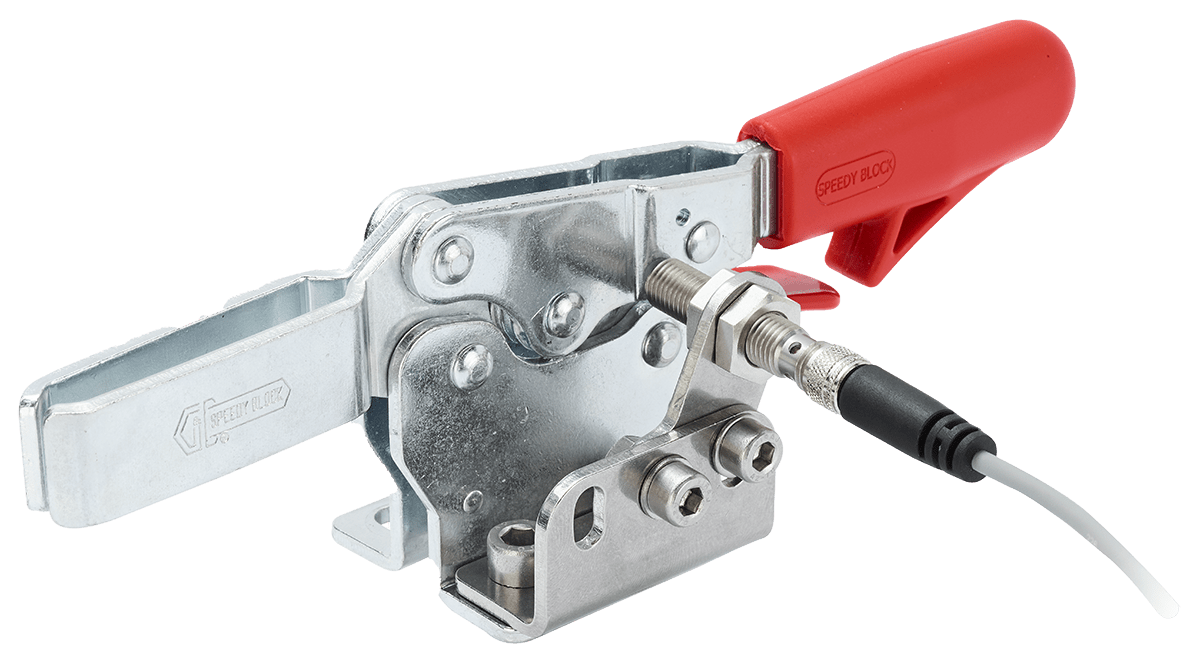

Application example on horizontal series

Industrial Applications

Proximity sensors are commonly used in various industrial applications such as machinery automation and production processes. They offer reliable and contactless detection with metallic objects.

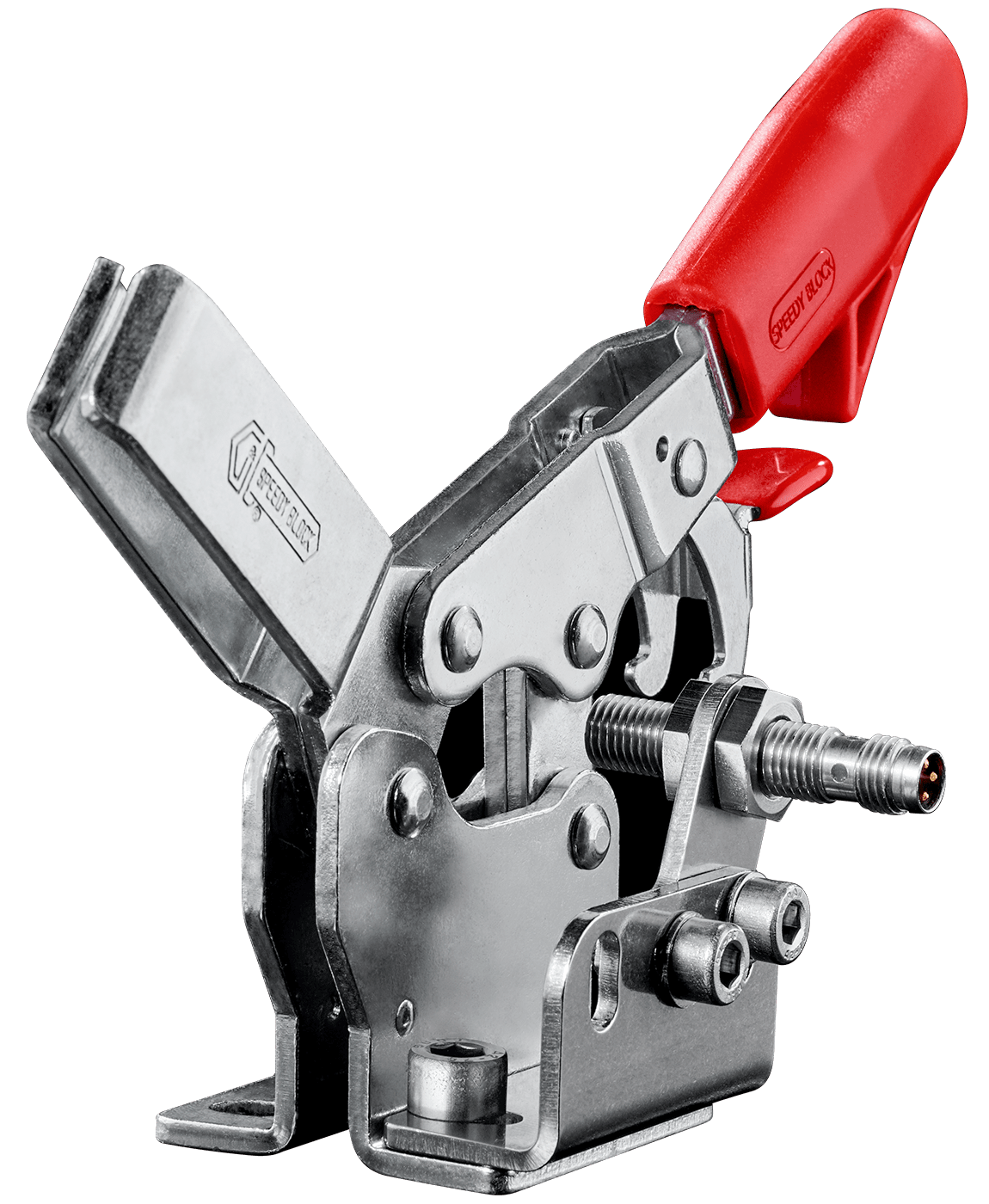

The Speedy Block Kit

Speedy Block offers for its clamping tools a support to be screwed onto the base of the tool and an inductive proximity sensor. These sensors play a crucial role in ensuring the correct positioning of mechanisms during industrial operations.

Benefits and Safety

By sending a signal of the tool’s closure or opening, the sensors prevent potential errors or damage to parts, thereby ensuring safety and quality in processes.

Technical Details of the Kit

It consists of a bracket to be fixed to the base of the tool and a sensor holder made of stainless steel AISI 304. The kit comes complete with a sensor. Its installation is adaptable to the needs of the application.

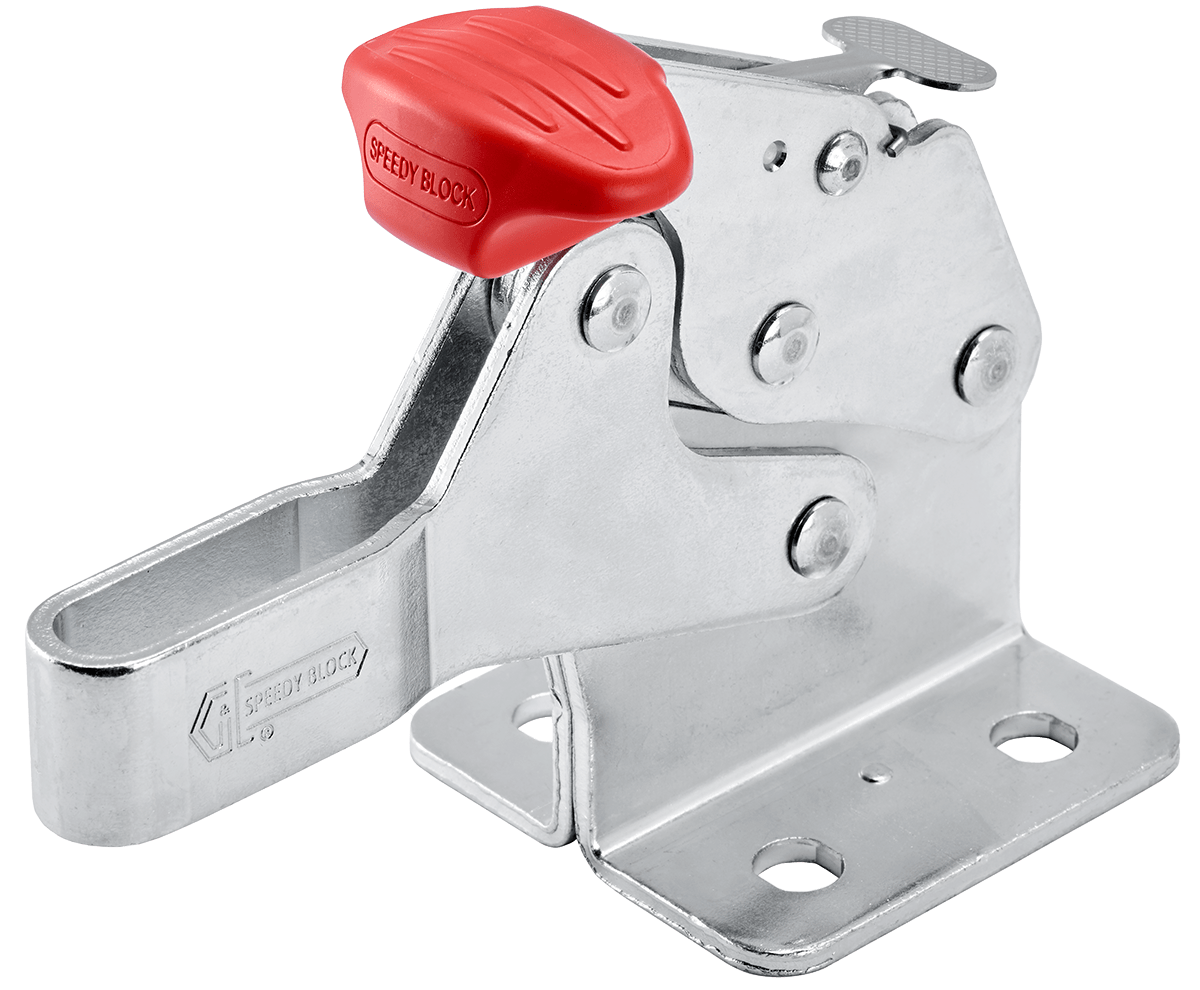

Horizontal series with folded base

Compact profile with reduced horizontal development. T-shaped ergonomic grip for easy opening. Ideal for closing lids or hatches of machines in motion or subject to vibration. The stainless steel version is suitable for sectors such as food, pharmaceutical, and chemical.

| Materials: | galvanized steel or AISI 304 stainless steel (MX-MLX) |

| Riveted bushings: | galvanized steel or AISI 304 stainless steel |

| Support bushings: | galvanized steel or 303 stainless steel |

| T-handle: | red color polyurethane; resistant to oils, greases and other chemicals |

| Safety lever: | galvanized steel (ML) or AISI 304 stainless steel (MLX) |

| Swivel pin: | galvanized steel or AISI 303 stainless steel |

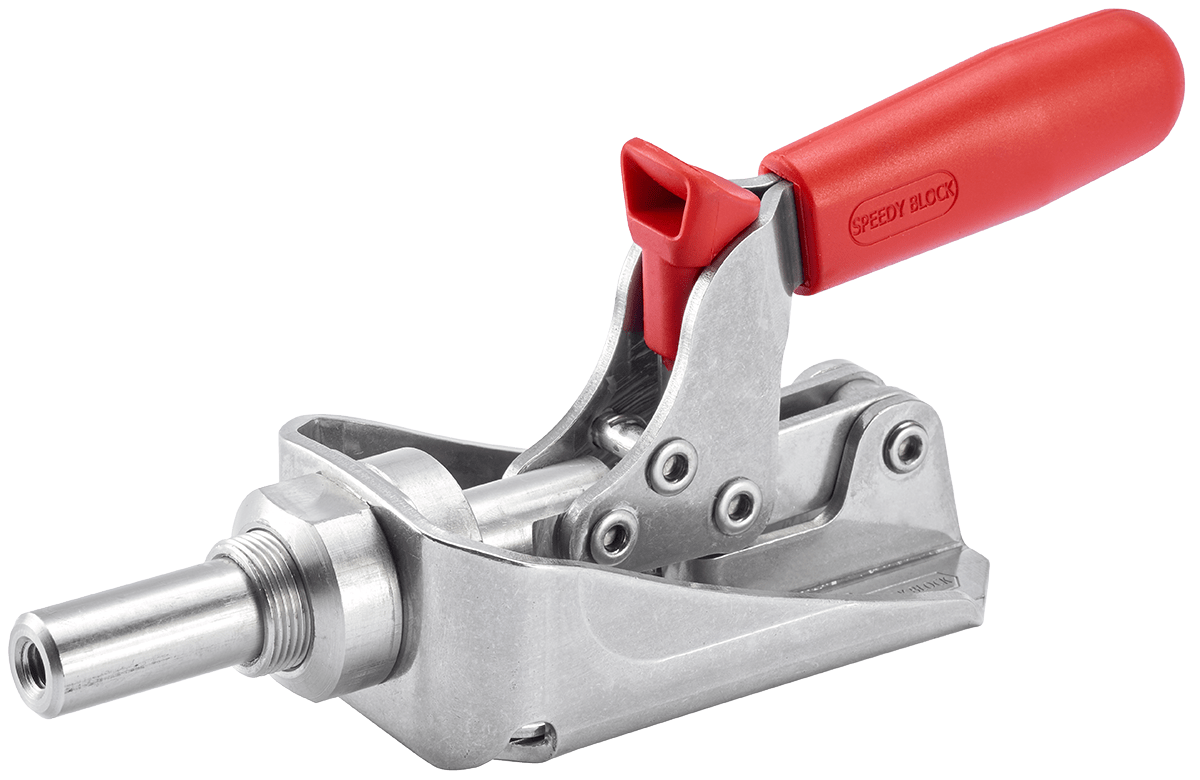

Only push straight-line action series

The clamping tools of this series can only operate in a push mode. The ASLX shape also features a special safety lever that ensures the perfect anchoring of the tool, preventing any accidental openings caused by vibrations or impacts. The stainless steel version is suitable for sectors such as food, pharmaceutical, and chemical.

| Materials: | AISI 304 stainless steel for sheet metal components and AISI 303 stainless steel for turned components |

| Handles: | red polyurethane; resistant to oils, greases and other chemicals |

| Safety lever (ASLX form): | AISI 303 stainless steel with ergonomic red PVC button |

| Spindles: | to be ordered separately |

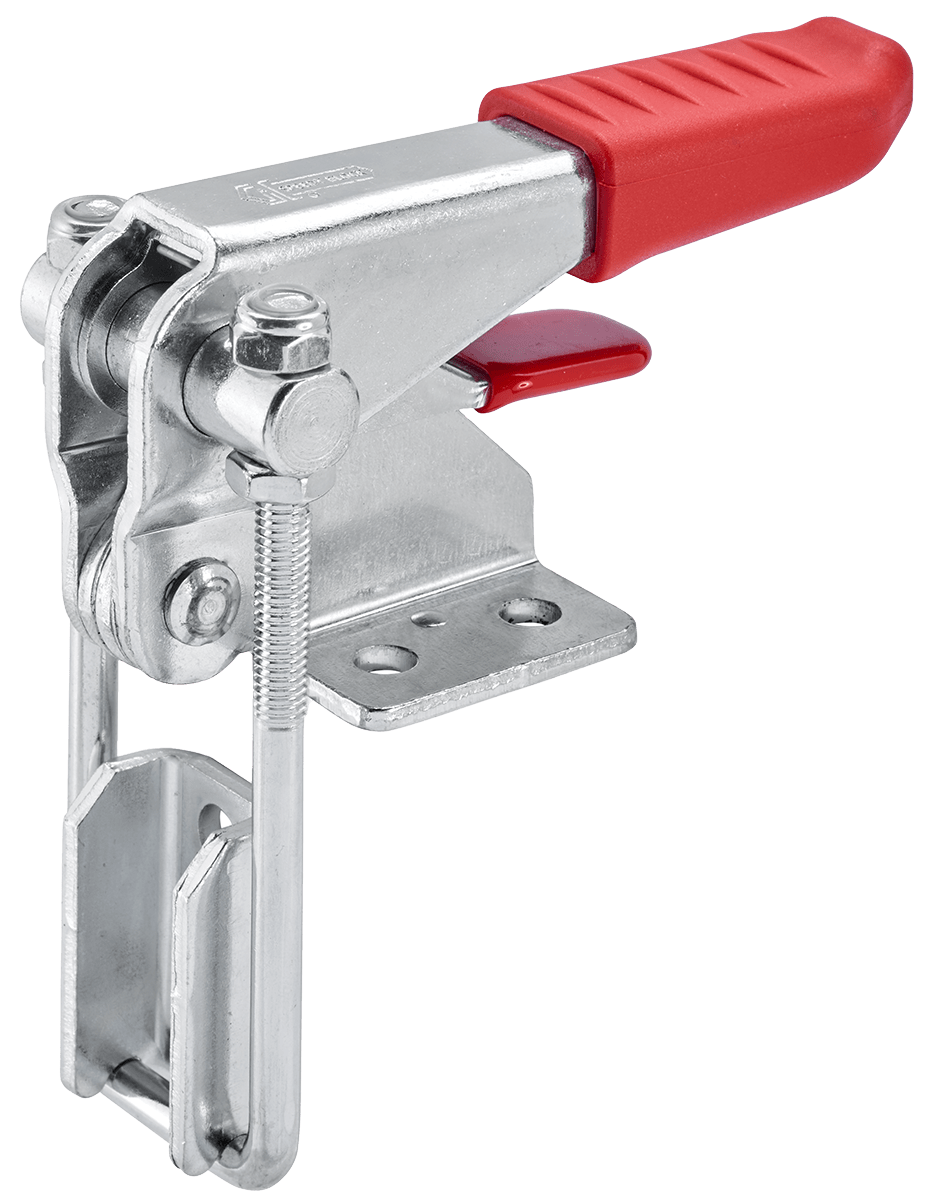

Double rod series (light performance)

Equipped with a safety lever, these tools are ideal for closing lids or hatches of machines in motion. The stainless steel version is suitable for sectors such as food, pharmaceutical, and chemical.

| Materials: | galvanized steel or AISI 304 stainless steel (T3LX) |

| Riveted pivots and rods: | galvanized steel or AISI 304 stainless steel |

| Swivel pin: | galvanized steel or AISI 303 stainless steel |

| Handle: | red polyurethane; resistant to oils, greases and other chemicals |

| Safety lever: | galvanized steel or AISI 303 stainless steel with ergonomic red PVC button |

| Execution: | the tool is supplied complete with u-shaped latch, catch and nuts |